Engineering: Where the Rubber Meets the Road

It’s one thing to create a beautiful aesthetic design but another to be able to take that design and engineer it for production.

At MDI we have an extremely talented and experienced engineering staff to get the job done. We’ve won industry awards, been featured in CAD magazines, and SolidWorks put one of our designs on their owner’s manual cover a few years ago. We’re good. Every production quote we deliver contains an extensive engineering analysis on the manufacturability of the design, mold flow analysis, tool design analysis, and more.

- Scientific Qualification with RJG Trained Master Molders

- IQ/OQ/PQ Full Capability Studies

- Mechanism development.

- Complex CAD surface modeling.

- Sheetmetal design and fabrication.

- Design of tooling ready, injection molded parts.

- Materials and process technologies.

- Design for assembly and cost reduction.

- Green materials research and design.

- Modular Tooling Systems

- In-House Tool Design

- Complete Tool Build Capabilities (In-house, 3rd party flex; NA and global sourcing as needed)

- 15 Tool Makers (including 4 apprentices)

- Wire and Electrode EDM

- CNC Mills and Lathes

What are you waiting for? Call us at today 1-800-852-1472 or use our contact page and we will respond within one business day to begin helping you with your design needs.

Q-Drive

2-4 Weeks

Q-Mold

6-9 Weeks

Dedicated

6-12 Weeks

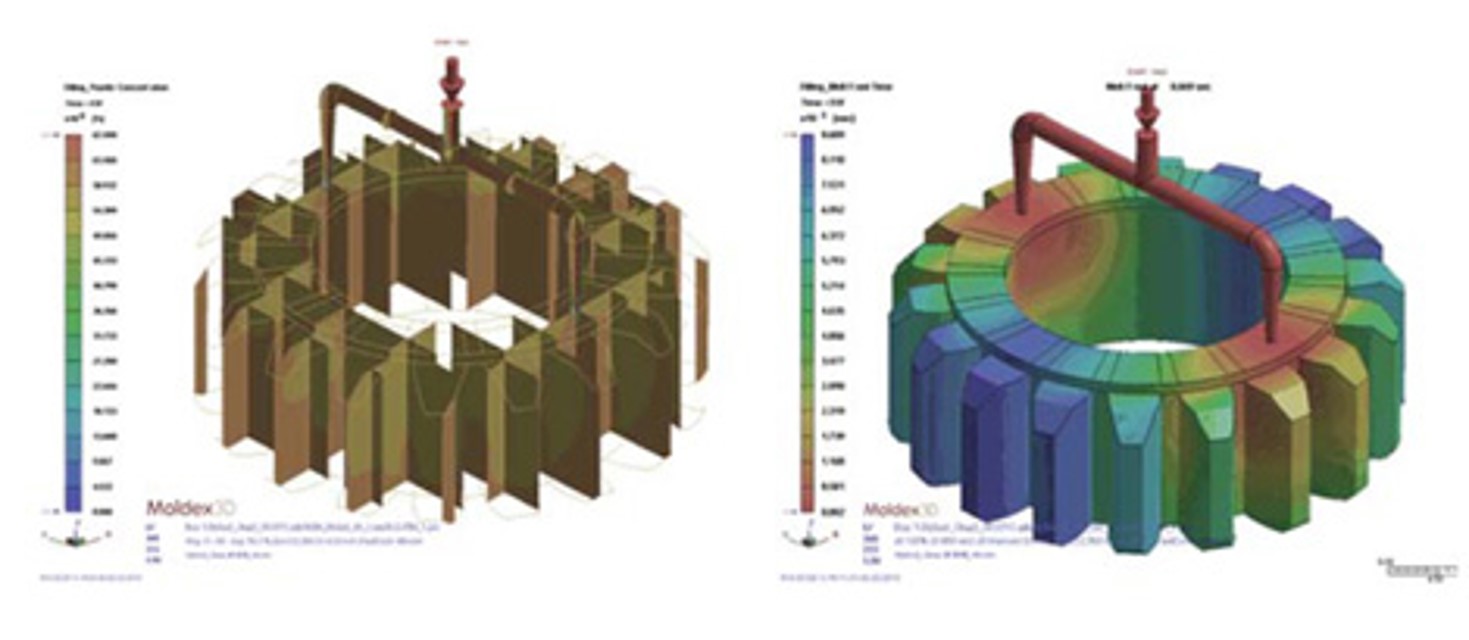

Mold Flow Analysis

- Thickness analysis,Filling analysis,Weld line analysis,Warping analysis,Deformation Analysis

- Modelling and simulation for injection molding process in advance are to pursue what may cause mold defects like deformation, shrinkage, short shot, and trap.

- The mold flow involves injection process, mold design, and material data, and drives the improvements on filling process and provides an entire solution.

- The mold flow helps to optimize the mold design, improve mold efficiency and cost competitiveness, and reduce lead time.

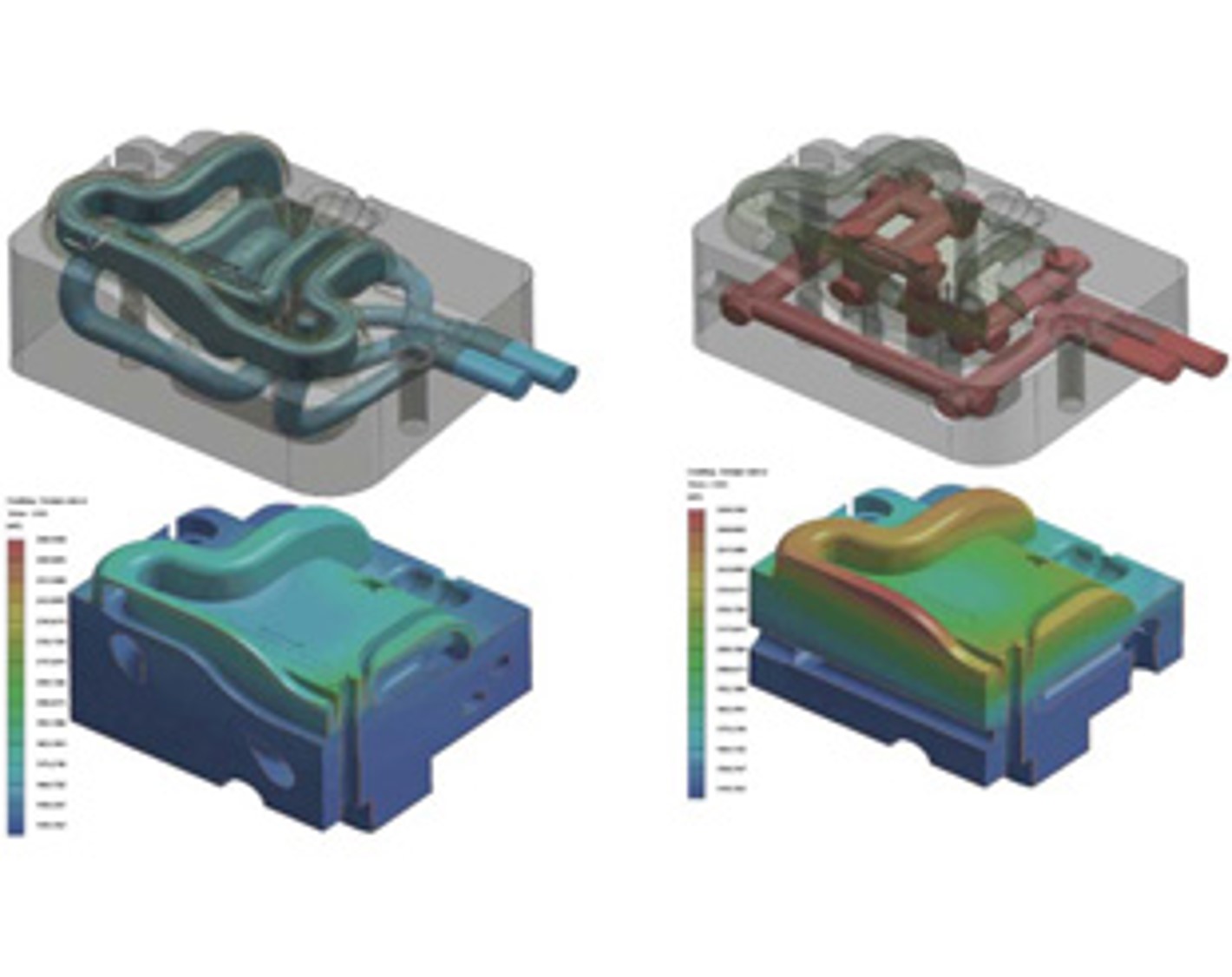

Conformal Cooling Technology

Precision metal 3D-printed

- Conformally-cooled injection molds design following the shape of the part

- Promote mold temperature uniformity in the plastic materials being molded

- Simulate and establish that the channel pressure and fluid flow in two diverging channels

- Modeling roughness and residual stress of inner wall within flow path

HAVE A QUESTION?

WE ARE HERE TO HELP!