Micro Metering Pumps

Overview

- Piston Pump provides precise metering of beverage concentrates and other fluids.

- Volumetric dosing accuracy: +/- 2% of set point, < 1 micro liter standard deviation.

- “True” Positive Displacement unlike diaphragm pumps subject to variable stroke volume.

- Accurately pumps high viscosity fluids up to 250 centipoise.

- Polysulfone pump head and wetted component materials are Food Grade.

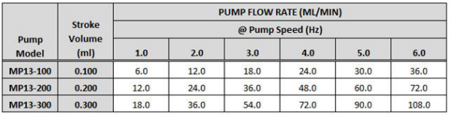

- Fluid Flow Rate up to 100 ml per minute.

- Fluid source is typically beverage concentrates and other fluids stored in atmospheric pouches.

- Seitz offers OEM customization to accommodate higher and lower flow ranges

Features and Benefits

- Very high metering accuracy is provided at a competitive price point.

- Reciprocating piston delivers precise stroke volume, each and every stroke.

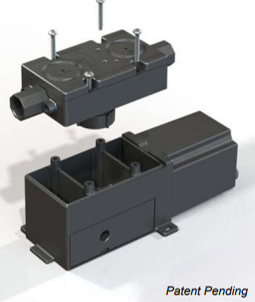

- Magnetically coupled piston pump head minimizes moving parts and promotes high reliability.

- Pump head may be replaced in seconds to higher or lower volume capacity. Potentially disposable like a printer cartridge. Economical to service.

- Small footprint requires minimal space.

- Pump evacuates an atmospheric product pouch (or fluid bag) greater than 99% without loss of metering accuracy

General Specifications

- Fluid Types: Liquids, Vapors and Gases

- Input Voltage: 24 VDC Nominal (18 VDC to 30 VDC allowable operating range).

- Nominal Power: 4.5 watts, 200 ma

- Nominal Stroke Volume: up to .300 ml currently developed.

- Stroke Speed: up to 6 Hz.

- Operating Pressures: Near atmospheric. Suction side up to 2 psig negative side pressure. Discharge side up to 6 psig positive pressure.

- Check Valve Cracking Pressure: 1 psi forward flow.

- Self priming up to 15 in. Hg dry suction vacuum.

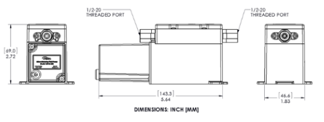

- Overall Dimensions: 5.6” long x 1.8” wide x 2.7” high.

- Motor Commutation: Brush Type (with optional capability for electronic commutation).

- Connecting Tube Size: .125” ID recommended for fluids with viscosity up to 25 cp. .188” ID recommended for fluids with viscosity up to 250 cp.

- Ports: Optional .125” or .188” Barbed Tube Fittings Provided. Alternate Connection: 1/8” NPTF or Sanitary Upchurch style.

Control Method

- Pump control module precisely regulates speed and commands the pump to dispense in discrete strokes on demand. Hall Sensor output confirms stroke position and speed.

- 3-Wire Pigtails Provided Power, 24 VDC Signal, 1.0 to 5.0 VDC Ground

- Pump speed may be selectively controlled either through analog or digital signal input.

- Analog Control: 1.0 to 5.0 VDC input linear with 1.2 to 5.0 Hz pump speed.

- Digital Control: Control will accept a signal cycled from zero to 1.0 — 5.0 VDC. Signal voltage must maintain for at least 20 ms before reverting state to zero volts for the control to recognize one (1) signal cycle. Each signal cycle results in one (1) pump stroke. If signal voltage remains steady, the control will interpret an Analog signal and regulate to the speed corresponding to the signal voltage.

Optional Features

- Accumulator ejector removes air from liquid suction (requires slightly positive suction pressure >=2.0 in. w.c.)

- Vacuum pressure activated “sold out” sensor provides failsafe shut-down when the product pouch is empty

- Brushless DC drive motor

- Custom wire connectors

Potential Applications

- Beverage Dispensing

- Medical Fluid Delivery

- Medical Diagnostic Equipment

- Food Dosing/Packaging

- Paint and Ink Dosing

- Fuel Cell Systems

- Water Analyzers

- Chemical/Gas Analyzers

- Disinfectant Dosing

- Soap/Detergent Dosing

HAVE A QUESTION?

WE ARE HERE TO HELP!